What are the propeller shaft and final drive?

The propeller shaft and final drive both are components of an automobile.

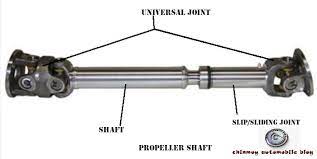

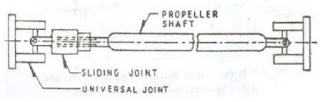

Propeller shaft:- Propeller shaft is a hollow circular shaft that is used to transmit the power or rotational motion from the gearbox to the final drive. It also includes the U- joints and slip or slider joint to adjust the length of a shaft when the vehicle is on a bump. The propeller shaft is inclined at a particular angle for length adjustment with the help of U-joints and slips joints.

Propeller Shaft And Final Drive

Final drive:- Final drive is the arrangement of the ring gear and pinion gear. The ring gear is also called a crown wheel, it is bigger than pinion gear. This arrangement is used to obtain the permanent reduction and transmits the power at 90°. The gears which are used here are the hypoid gears. This arrangement is located in the differential casing. Here the power coming from the gearbox through the propeller shaft is divided into two-axle or a half shaft.

A propeller shaft is a shaft that transfers the power developed in the engine to the wheels with the help of a gearbox. It consists of universal joints which allow the propeller shaft to move linearly when the wheels of the vehicle run over an uneven surface.

The final drive is also known as ‘differential’ which allows the rear wheels to turn independently. For example, if a vehicle is taking a right turn, its innermost wheels have to cover less distance and its speed will be less. But the outermost wheels will have to cover relatively more distance and also at higher speeds compared to the inner wheels. This can be achieved with the help of the differential.

The propeller shaft and final drive both are components of an automobile. Propeller shaft:- Propeller shaft is a hollow circular shaft that is used to transmit the power or rotational motion from the gearbox to the final drive.

- What are the differences between a propeller shaft and a drive shaft?

- What are the functions of a propeller shaft?

- What are the three main parts of the propeller shaft?

As the name suggests, It's a shaft that transmits engine power to the wheel through the gearbox at one end and rear axle at others.

It's can be a single piece or multiple, depending on the configuration of the vehicle like overall length, No of axles,s, etc.

- The basic principle that should be taken care of while designing the propeller shaft is its torque carrying capacity. It must be capable to take care of the torque developed by the engine.

- Load, vehicle duty cycle, engine torque, gear ratio, axle ratio, and vehicle layout are the multiple design parameter for the propeller shaft.

- Final drive - It's the last set of gear combinations in the driveline like in the case of the rear axle. Rotational torque is transmitted through the prop shaft to the rear axle in the case RWD vehicle.

What is the difference between a propeller shaft and a universal joint?

Similar to the difference between your forearm and your elbow.

Why is a hollow propeller shaft not a solid shaft used in a car?

The power transmitting capacity of the hollow shaft is more than the solid shaft when both have equal area.

Since there is no limitation of space in the car or any other four-vehicle therefore hollow shaft is used.

But if there is a space limitation then the solid shaft is preferred over the hollow shaft.

Why is a propeller shaft tubular?

This is majorly attributed to the two following reasons:

- Avoid Sagging

- Sagging is the bending of the shaft due to its own weight. This not only develops vibrations but also generates more wear. To avoid this phenomenon shafts are made with hollow tubular cross-sections to reduce their weight.

- Increase Torsional resistance

- Has proved, hollow tube light reception has a more polar moment of inertia does they can resist the higher twisting moment and hence, reduces wear rate.

What is the propeller shaft?

A propeller shaft is incorporated for the transmission of power in the vehicle. They are exposed to heavy load and stress which results in gross misalignment of the wheels. In extreme cases of misalignment; the force generated can cause excessive wear and breaking of the shaft.

The propeller shaft connects the gearbox to the final gear of the vehicle through Universal Joint Cross (UJ Cross) and Centre Bearing which serves as a drive shaft. The propeller shaft of vehicles are sufficiently long and operates at a very high speed. Filtrum propeller shaft parts are designed to provide superior resistance to misalignment along with efficiently absorbing undesired vibration.

How do I inspect a propeller shaft?

- I haul the boat, pull off the prop, and send it off to the prop shop, where it's polished and balanced.

- I break the shaft free and hopefully, it won't be necessary to remove the rudder.

- I pull the shaft, and it goes out to be magnafluxed and checked for straightness.

- Especially important is the part that passes through the stuffing box, and through the stern gland.

Occasionally, I've had to have a new shaft made upon finding a hairline fracture. I also never attempt to straighten a warped shaft. Better to replace it.

Can one vehicle have a two-propeller shaft?

Yes, vehicles do have two propeller shafts. And they are not spilled.

All AWD and 4WD have two propeller shafts.

What are the advantages of the tubular propeller shaft?

In a cylindrical shape, most of the torque capacity is at the surface or edge of the cylinder. Think of it as a series of levers, where the surface that is furthest from the center has the most leverage. So if the outside provides most of the torque capacity, there isn’t a lot of purpose for carrying the rest of the weight of the inside of the shaft.

If you have a 2″ propeller shaft that is hollow, and one that is solid, the hollow one will have nearly the same torque capacity as the solid one, but a fraction of the weight. So why would you want the solid one? And if you make the hollow shaft 2 1/4″ diameter, it will be considerably stronger than the 2″ solid one, but still, weigh dramatically less.

Also: CRDI explained.

Why is a propeller shaft not made continuous?

Therein lies the problem with the question

propeller shafts are used in many applications in boats to drive the propeller, in aircraft to drive the propeller and in vehicles to connect the transmission to the differential so to get the right answer you have to define its application

Assuming that it is for vehicles, the problem is that over a certain length, the torque effects make the center of the shaft tend to whip and create an unbalance Lengths over 6 feet have problems and so the shaft is divided to maintain lengths of under 6 feet that is why on long bed trucks and buses there can be 4 tail shafts under the vehicle

How is a two-piece propeller shaft aligned?

You can do this quite successfully with a dial indicator.

However, it does take a bit of skill and practice, and trying to explain it here is unlikely to be successful.

Find yourself a good maintenance fitter who is used to doing this sort of job and get them to demonstrate to you how to do it.

Then have a go yourself. You will find it harder than you think.

You can also buy electronic equipment that does the same thing, which works extremely well, is quicker, and typically more accurate than most people can achieve, but it is not particularly cheap. (with apologies to all the skilled fitters who can do alignments with dial indicators)

Alternatively, you buy yourself a suitable coupling, do a coarse alignment with a ruler, and live with the results, like many people do.

What is the function of a universal joint in a propeller shaft?

Couplings are generally used to connect two power transmitting shafts. When the two shafts are collinear we go in for the use of Flange couplings. However, when the two shafts are inclined to one another we go in for the Universal coupling or Hooke’s joint.

Now, why is it we require the use of a Universal coupling in an automobile? The engine is mounted at a higher level and it is connected to the gearbox through the clutch flywheel assembly. But the road wheel is at a lower level because of the smaller size of wheel. If the gearbox is to be connected to the differential, the propeller shaft will have to be slightly inclined downwards. Hence we use not one but two Universal couplings one on either end of the propeller shaft as shown below.

Since there will be variations in the height of the differential pinion that engages with the crown gear the axial movement and also vertical movements are accommodated by the splines on the telescopic propeller shaft and the Universal coupling respectively.

What are the advantages of a propeller shaft?

They are found on vehicles with a diff at the rear. The advantage is that without one you go nowhere. Are there other ways to propel a vehicle? Yes, you could use an electric motor in the wheels and the propeller shaft is replaced by wires. You could also do this with hydraulics but would be noisy and inefficient.

To date, the conventional steel propeller shaft is the cheapest and simplest method of transfer of torque from the transmission to the diff to be invented.

What material is used to make a propeller shaft?

I've personally never worked on prop shafts myself. But I believe it should be forged steels like 16MnCr5 or probable C15E which will be heat treated accordingly for toughness and strength.

The heat treatment is equally as important as the material which is going to be used for such applications.

What are the differences between a propeller shaft and a drive shaft?

Q: What is the difference between a propeller shaft and a drive shaft?

A: On a forward engine, RWD car the terms are synonymous.

What is the operation of a propeller shaft?

It will transfer the power from the gearbox(transmission) to the differential. It's connected with the use of universal joints

What are the causes of the failure of the Propeller shaft?

- Bad U-Joints are the most common problem.

- Bad transmission mount.

- Worn spines.

- Bad suspension parts on the differential.

- Bad driving habits

- Too small for the power it needs to handle.

Worn bearing on the output shaft of the transmission and/or input shaft of the differential.

How is the length of a propeller shaft varied automatically?

Hahahaha

An interesting question. Actually what is altered is the pitch of the propeller not the length of the propeller shaft.

The purpose is to reduce the power and direction of thrust produced by the propeller.

How is the propeller shaft constructed?

The propeller shaft in what? There are two different types of aircraft (piston engines or turboprops) and at least two different types of ships (ships and submarines)

All perform the same task but are also constricted slightly differently.

It occurs to me that the drive shaft in a front-engine rear-wheel-drive shaft is also called a propeller shaft, but that’s an entirely different thing!

What are the functions of a propeller shaft?

The main function of the propeller shaft is to connect two mechanical elements or components i.e. one is a driving element and another is a driven element. We can transmit torque/turning moment and power from one component to another which are apart at some distance. The propeller shaft in a vehicle and ship just connects the main engine to the power drive which drives the vehicle or ship.

The main failure which is generally observed in the propeller shaft is the twisting moment due to excessive shear stress. By proper designing of the shaft, we can overcome this failure.

What type of engine turns a propeller?

One with a central rotating shaft, for example, piston, turbine, and rotary engines may be used to turn a propeller.

How are propellers fitted to the shaft?

On my sailboat, there's a conical taper to the shaft and the inside of the propeller, so it fits snugly in place. It's held against reverse thrust by a nut on a thread cut into the end of the shaft, held in turn by a split pin through a small hole in the shaft. There's also a keyway cut in the shaft and prop with a metal key that stops the prop from slipping on the shaft.

Why is a slip joint important between a gearbox and a propeller shaft?

A slip joint is present in the propeller shaft to be exact. The propeller shaft takes power from the gearbox and delivers it to the differential .when ever the vehicle passes over a number or a pit the differential traces a path of arc, which exerts an axial force on the propeller shaft which in turn is transferred to the gearbox. I lock the degree of freedom of the suspension in other terms. In order to avoid this, a slip joint is provided which allows the propeller shaft to vary its length .so that it varies in length without any restrictions to the suspension system

Comments

Post a Comment